Main Features of Metalworks’ Bags Slitting & Emptying Machine

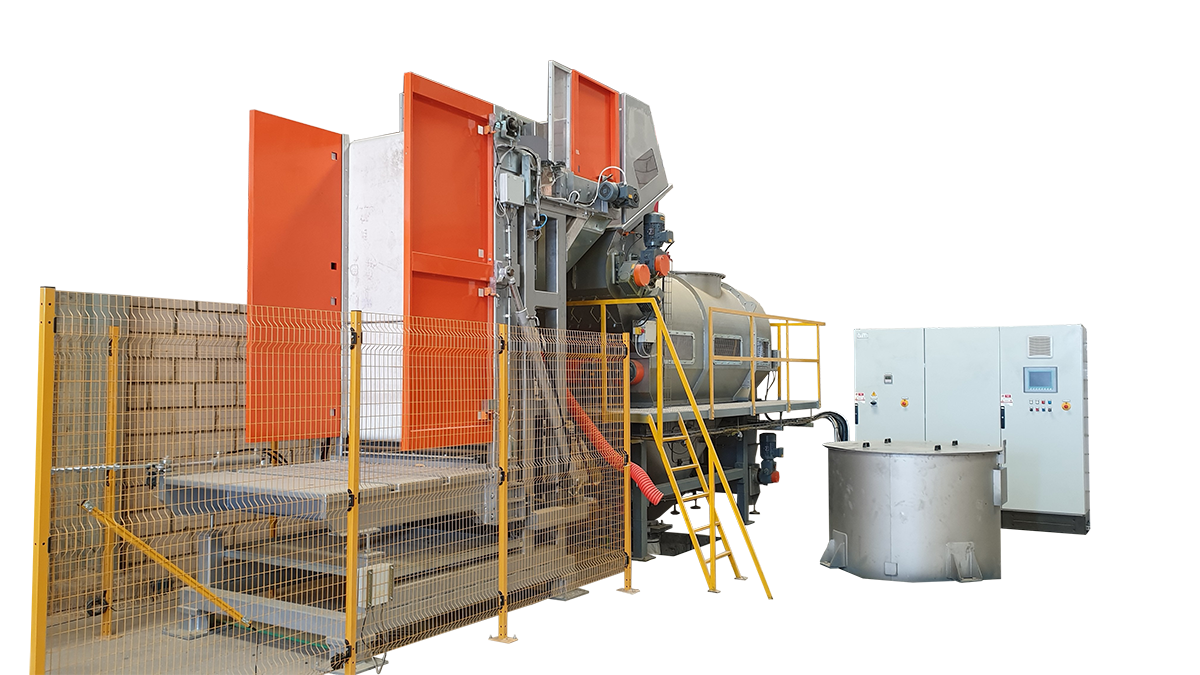

Metalworks bags slitting and emptying machine represents the latest most advanced technology for bags slitting and

emptying complete with de-palletizer and empty bags compactor.

Metalworks machine is designed and manufactured for heavy duty operations. It is strong, efficient and reliable suitable

for high performances (up-to 1.000 bags /h) and unbeatable emptying efficiency (up-to 99,9 %).

Metalworks machine mainly consists of:

– De-palletizing

– Bags slitting

– Bags Emptying

– Empty bags compacting

– Electric driving and controlling panel

Option :

– Automatic stuck-up of empty pallets

– Magazines for full pallet storage

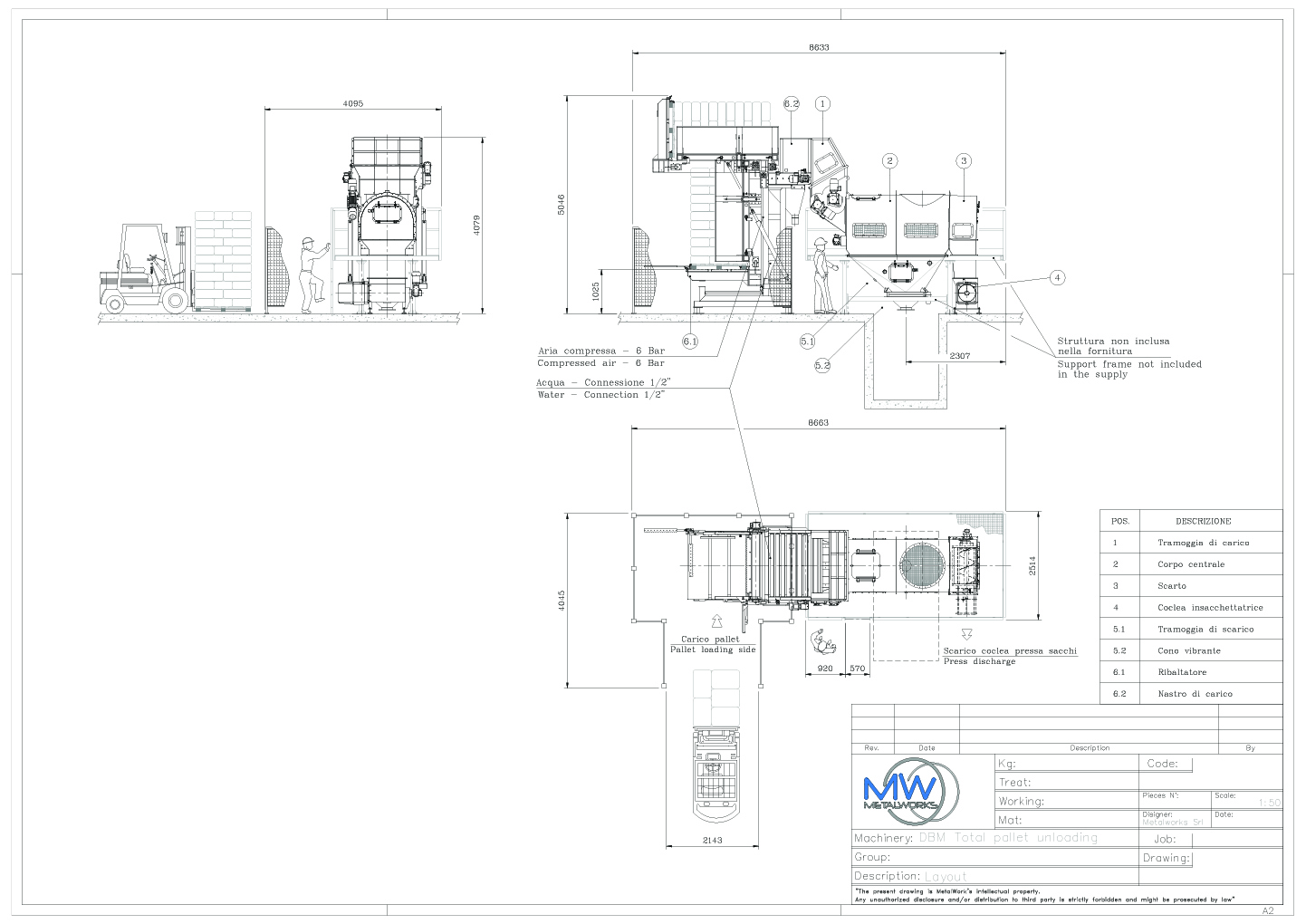

De-palletizer

De-palletizing is made by hydraulically tilting the entire pallet on belt conveyors feeding the rotating knifes the machine

is equipped with. In this way higher efficiency, easier and safer operations along with less demanding maintenance is

granted.

Experienced proves that Metalworks design is granting a great: 1. The entire machine, especially the de-palletizer, is designed and build for heavy duty operation and reduced

maintenance

2. Bags are surely and gently handled. Pallets are hydraulically lifted and tilted. Bags, using two inline conveying

belts, are fed into the machine and automatically slit.

3. Handling, slitting and emptying can be surely and consistently ensured though the following might be

experienced:

– In case of damaged bags

– The bags (the layers consist of) are not sufficiently flat

– If, due to longer exposure to the sun or, as happens, bags are glued in order to ensure stability especially

during land transportation

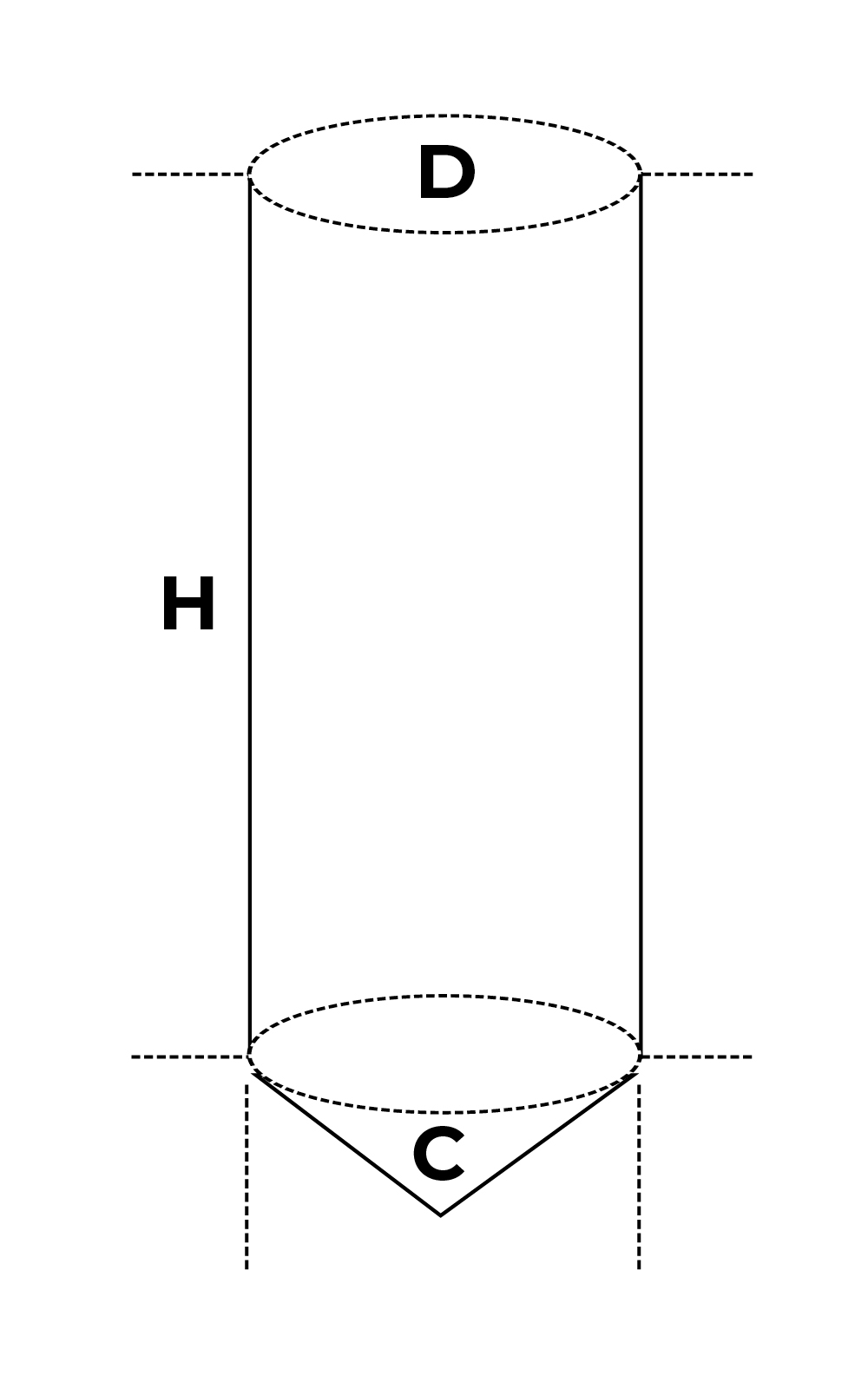

4. The discharging cone of the machine is fitted with a vibrated safety grid that can segregate larger items that can

be removed thanks a large hinged lid the cone is equipped with.

BAGS SLITTING

BAGS EMPTYING

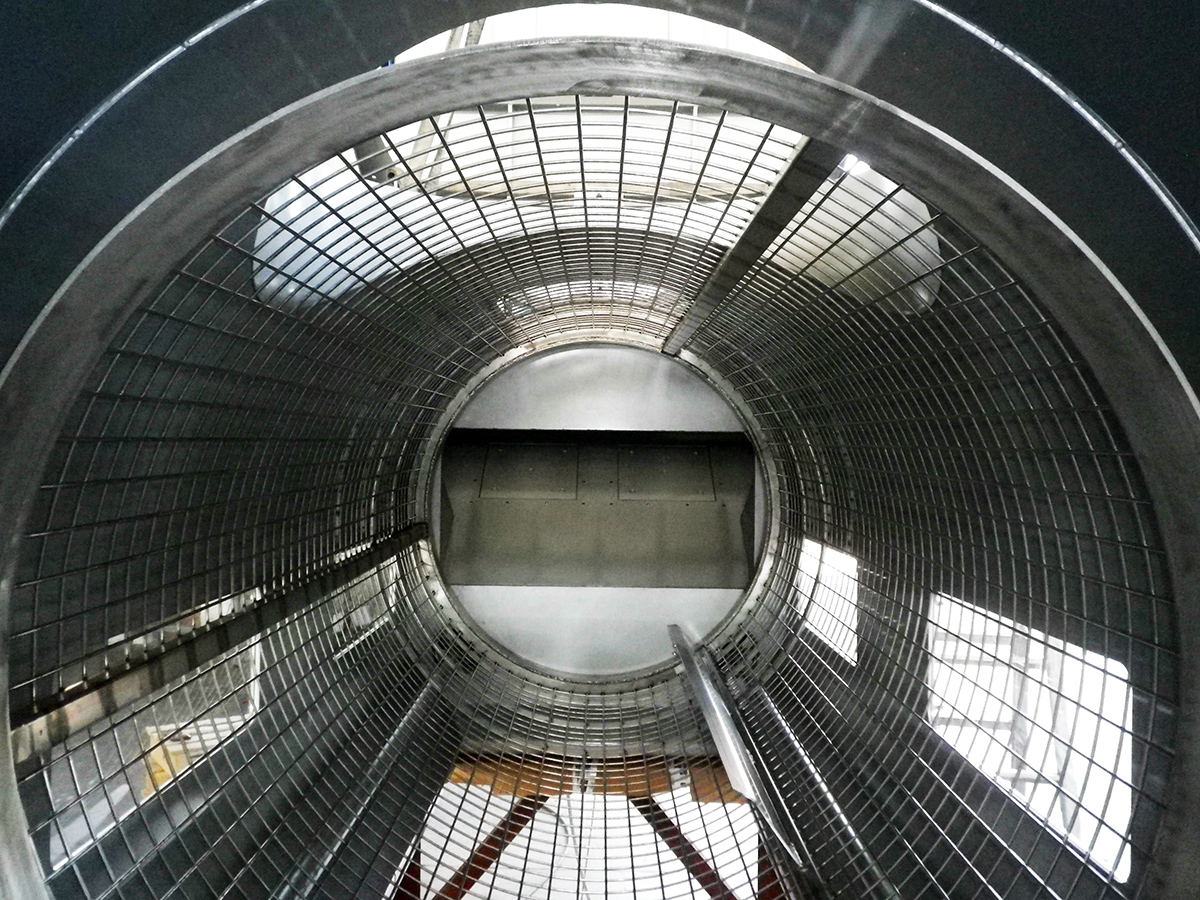

Metalworks grants the full Bags Emptying by intensive tumbling of slit bags moving into a rotating drum. The result is

an accurate emptying of bags, direct discharging of debagged product into the machine hopper, automatic gathering

and feeding of empty bags into the empty bags compactor. Simple, effective and reliable as a heavy-duty highly and

flexible machine needs to be.

Experience proves that other machines available on the market , mostly due to economic reasons, are slitting the bags

(each layer consists of) by “sliding” the entire layer of bags on rotating blades. The matter is, as it often happens, that

the bags are not evenly sitting thus, are not uniformly slit and might fall into the machine hopper, without even getting

slit too.

Poor slitting will make the subsequent mechanical “shaking” not suitable to the full emptying of the bags. In fact, some

granules will be retained that inevitably will get lost with the empty bags.

Shaking, among others, leads to additional vibrations whose negative consequences are increased and faster wearing

and frequent and costly maintenance.

Empty bags compacting

Once the bags are slit and emptied they automatically and continuously moving into an empty bag screw compactor.

filling a PE plastic tube for easy handling. Once the PE tube is full an alarm signa will be provided for its replacement.

BAGS EMPTYING

Metalworks grants the full Bags Emptying by intensive tumbling of slit bags moving into a rotating drum. The result is

an accurate emptying of bags, direct discharging of debagged product into the machine hopper, automatic gathering

and feeding of empty bags into the empty bags compactor. Simple, effective and reliable as a heavy-duty highly and

flexible machine needs to be.

Experience proves that other machines available on the market , mostly due to economic reasons, are slitting the bags

(each layer consists of) by “sliding” the entire layer of bags on rotating blades. The matter is, as it often happens, that

the bags are not evenly sitting thus, are not uniformly slit and might fall into the machine hopper, without even getting

slit too.

Poor slitting will make the subsequent mechanical “shaking” not suitable to the full emptying of the bags. In fact, some

granules will be retained that inevitably will get lost with the empty bags.

Shaking, among others, leads to additional vibrations whose negative consequences are increased and faster wearing

and frequent and costly maintenance.

Option

In order to increase the capacity of the machine and limit to the minimum the dead time for unloading the

empty pallet and load the upcoming full pallet, the machines can be equipped with the following option:

Automatic stuck-up of empty pallets:

It can automatically stuck-up up to 6 empty pallet that once reached can be collect ed and removed in one go by forklift.

Full pallets magazine:

A roller conveyor, in automatic mode, can store and move full pallets for the feeding of the automatic de-palletizer machine. Depending from logistic and available space 3 to 5 complete pallets are loaded on the full pallets magazine.